Hyundai x RISD Research Collaborative: Designing for Symbiosis is a collaborative study focused on a deep biomimicry approach to sustainable futures.

In collaboration with Jason Liao :)

Design Challenge and Nature Question:

How might we optimize space through materiality and structure for the car interior that does not compromise comfort or protection?

how does nature optimize space and modify physical shape?

Biological Strategy: Earwigs

Earwigs have a complex series of joints enables earwig wings to spring from folded to flight without the use of muscles. Structure that simultaneously supports the folding process and flight, all controlled passively by stored energy within the structure itself.

Research:

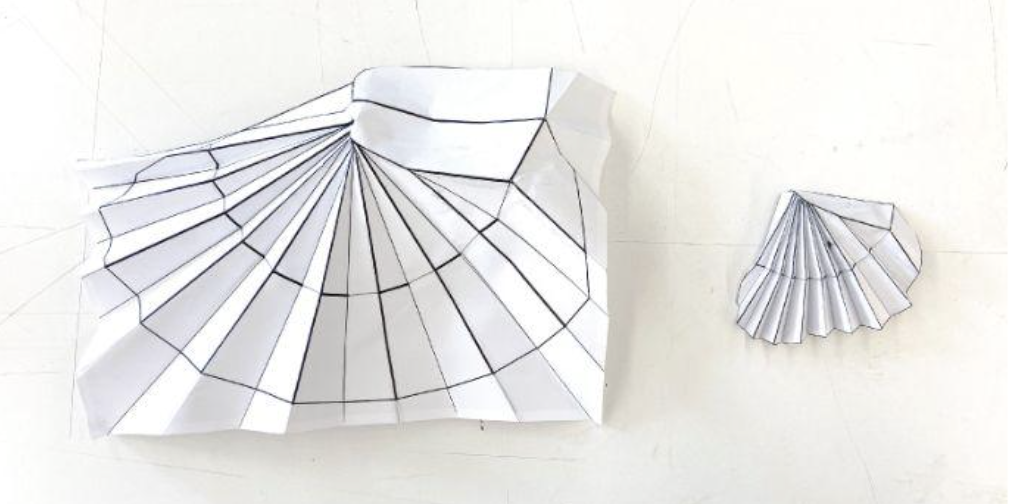

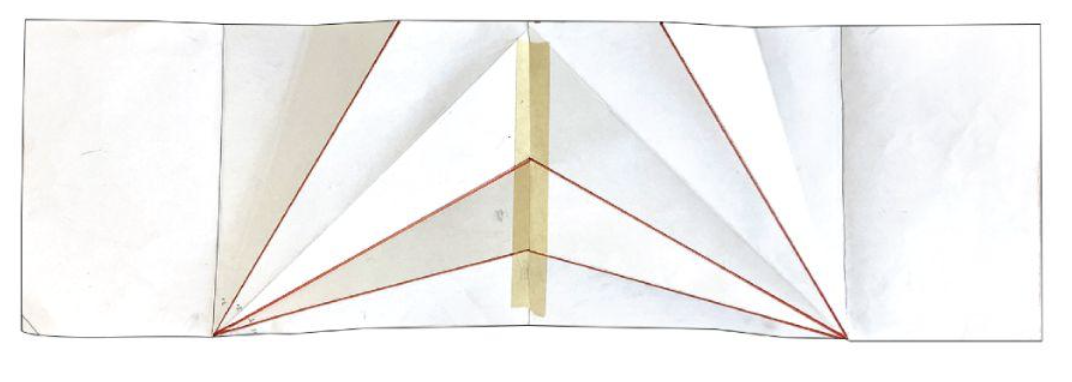

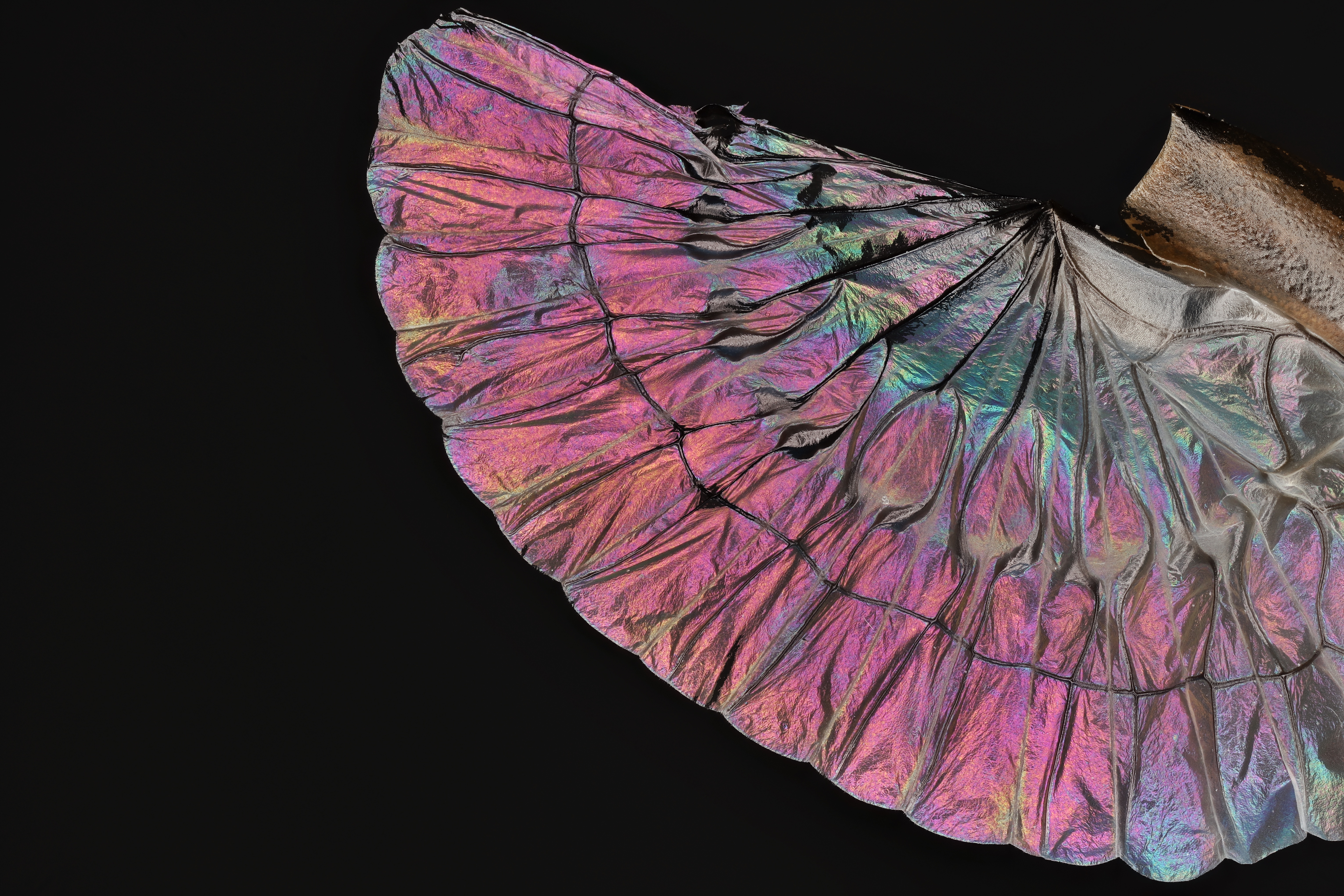

We investigated the folding mechanism through paper experimentation and studying the wings under the microscope in the nature lab.

.

.

.

.

Started prototyping on the Dobby loom using a muira fold since it simulataniously folds inwards and outwards like the earwig wing.

PIQUE THREADING - STRAIGHT DRAW - STITCHING WARP BLOCKS OF 4 REPEAT: 3.3 in

AVL DOBBY LOOM

WARP (72 epi) :

GROUND: POLYESTER 48 ends per inch

STITCHER: COTTON 24 ends per inch Sample A

-Cotton, polyester

-Looses its fold creases if left open

Sample A:

-Cotton, polyester

-Looses its fold creases if left open

Sample B:

-Cotton, polyester, polyurethane yarn

-Very stiff

-Difficult to fold back properly

Sample C:

-Cotton, polyester and a metallic yarn

-Closely related to the earwig wing color inspiration

Sample D:

By inserting chip boards pieces into two textiles layers, we created a framework that allowed us to better understand the production process of the design, as well as its potential uses.

Actuation Prototypes:

Nitinol is a heat-actuated thread. Can be actuated through passive heating and no external power supply is required

Experiment A:

Final Experiment:

Challenges:

- Equipment

- Downside of the dobby looms is that there is only 24 harnesses and the repeat/scale can only go so big. Constraints with the threading as well.

- Jacquard industrial loom

- Can make fabric at a bigger scale

- 24 inch repeat

- Freedom with the woven structure

- Nitinol

- Has to be heated at a certain temperature and does not revert back to its original shape when cooled

- Heat gun can only heat a certain area and doesn’t affect all the nitinol wires embedded in the fabric